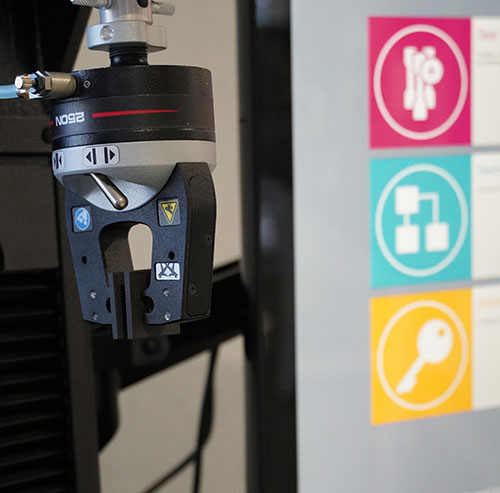

Over the past twenty years, the Instron Universal Testing Machine has become a critical and useful tool in the qualification of medical device and drug product package systems. In basic terms, the Instron is a test system, fitted with a calibrated load cell, that enables testing based upon forces of push and pull. Common Instron test functions include tensile, compression, bend, peel, tear, shear, friction, puncture, and other mechanical tests. With the development of many new and unique product presentation systems, to include pre-filled syringe package systems, patient specific lidded trays and product pouch systems, the value of Instron testing has only become more pronounced. To address the expanding trend of using the Instron Universal Testing machine as a quality control and qualification test platform for container and package systems, Instron has continued to develop and support a wide variety of test options. One key support platform is the Instron technical website that provides very detailed and specific information on many of the common Instron qualification tests. This article will serve to highlight some of these tests and provide direct leaks to these Instron generated educational tools.

Over the past twenty years, the Instron Universal Testing Machine has become a critical and useful tool in the qualification of medical device and drug product package systems. In basic terms, the Instron is a test system, fitted with a calibrated load cell, that enables testing based upon forces of push and pull. Common Instron test functions include tensile, compression, bend, peel, tear, shear, friction, puncture, and other mechanical tests. With the development of many new and unique product presentation systems, to include pre-filled syringe package systems, patient specific lidded trays and product pouch systems, the value of Instron testing has only become more pronounced. To address the expanding trend of using the Instron Universal Testing machine as a quality control and qualification test platform for container and package systems, Instron has continued to develop and support a wide variety of test options. One key support platform is the Instron technical website that provides very detailed and specific information on many of the common Instron qualification tests. This article will serve to highlight some of these tests and provide direct leaks to these Instron generated educational tools.

Many of the Instron test specific to container and package systems are based upon ASTM methods. As such, Instron has a dedicated index of all relevant ASTM methods that can be easily searched and navigated: https://www.instron.com/en-us/testing-solutions/by-standard/astm

ASTM F88 Seal Strength of Flexible Barrier Materials measures the peel strength of medical packaging in one of two peel configurations under normal ambient temperatures. This is a common test for pouches and lidded tray package systems. https://www.instron.com/en-us/testing-solutions/by-standard/astm/astm-f88—seal-strength

ASTM D638 is the most common testing standard for determining the tensile properties of reinforced and non-reinforced plastics. With the use of plastics being at an all-time high, it is critical that manufacturers be able to properly gauge the mechanical strength of their materials used in the production of plastic packaging systems. https://www.instron.com/en-us/testing-solutions/by-standard/astm/astm-d638

In addition to numerous ASTM specific resources available, Instron also address specific test options based upon the type of container or package system (in most cases in reference to a specific ISO standard) with their Biomedical Knowledge Center: https://www.instron.com/en-us/industry-solutions/biomedical#pharmaceuticals

ISO 11040 is a testing standard that addresses the design and functional properties of prefilled syringes. ISO 11040 is used primarily within the pharmaceutical industry and is critical for ensuring that syringes work properly in a clinical setting.

Glass Syringes – syringes are critical medical devices that allow medication to be delivered safely and efficiently at very precise doses. Because of their importance, it is crucial that hypodermic syringes perform as expected at all times. A leaking syringe can result in improper medication dosing and wastage and cause procedures to be delayed. The force required to expel liquid from the syringe must also be small enough to ensure that any medical professional can perform the task without resistance. https://www.instron.com/en-us/testing-solutions/by-standard/iso/iso-7886-1—syringe

Syringe Needles – There are multiple testing standards outlining methods for evaluating straight stainless steel needles used in healthcare applications. These standards are used by injection device manufacturers and the pharmaceutical companies that use them for drug delivery. Testing standards for syringe needles are necessary in order to regulate the products that reach the end-user. https://www.instron.com/en-us/testing-solutions/by-standard/others/syringe-needle-testing

Glass Vial and Rubber Stopper – Parenteral products such as injectable medications and vaccines are commonly packaged in glass vials. These vials must maintain a robust seal between the glass vial and the elastomeric closure to prevent product contamination and leakage. Residual Seal Force (RSF) is an evaluation of the quality of this seal. https://www.instron.com/en-us/testing-solutions/by-standard/others/residual-seal-force

These Instron based test examples are just of a few of the many test options available for package and container systems. The value of use and functional testing that the Instron machine and methods can deliver has become a critical part of the system qualification process. In those situations where a specific ASTM or ISO method exists, the combination of the Instron Machine, its user-friendly, Part 11 validated software and an experienced analyst can develop and validate a package system specific method that meets the qualification expectations.

These Instron based test examples are just of a few of the many test options available for package and container systems. The value of use and functional testing that the Instron machine and methods can deliver has become a critical part of the system qualification process. In those situations where a specific ASTM or ISO method exists, the combination of the Instron Machine, its user-friendly, Part 11 validated software and an experienced analyst can develop and validate a package system specific method that meets the qualification expectations.

The CS Analytical team has many years of experience working with Instron test methods specific to container and package systems and can help design a program that meets all regulatory requirements and client expectation.