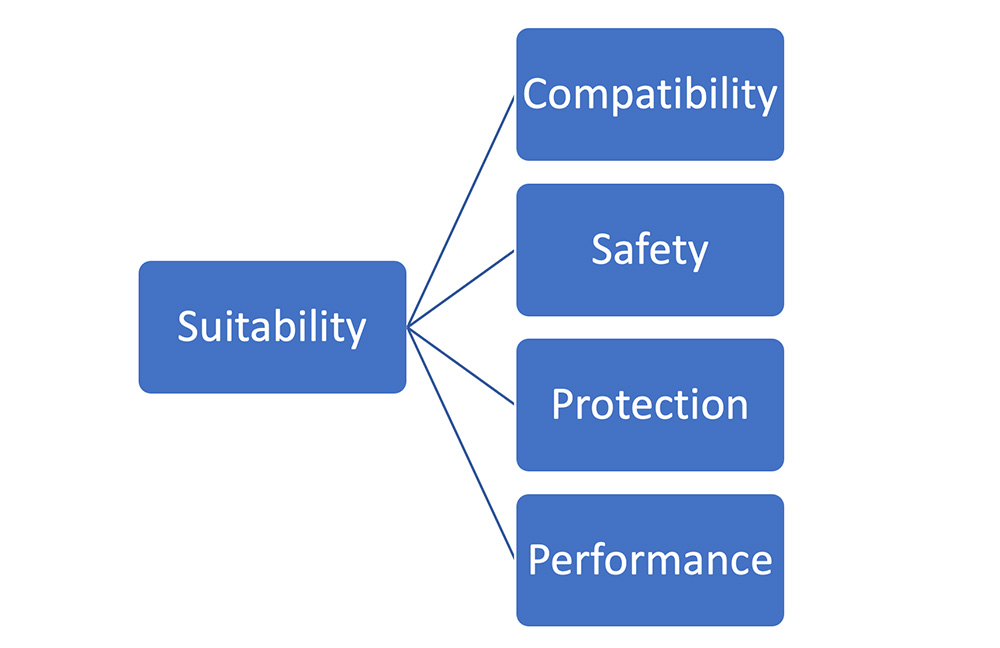

The process of qualifying a bio/pharmaceutical product container has many elements. The 1999 FDA Guidance for Industry on container closure systems sets expectations to which package systems are still held today. Ultimately, the onus is on the manufacturer to demonstrate that the package system is suitable for its intended use. This phrase, while vague, is broken down into demonstration of key attributes: compatibility with the drug product, such that the package system does not have a deleterious effect on product quality or efficacy, safety, such that the package or its components is not additive in a harmful manner, protection, and performance.

To demonstrate these attributes, compendial methods are often implemented, as encapsulated in multiple pharmacopeia worldwide, most notably the USP and EP. Testing can be thought of in two distinct “groups” , incorporating USP requirement chapters (those with a chapter number under <1000>), and guidance chapters (those over <1000>), summarized below. Whereas historically, USP packaging chapters were largely organized according to the test article, substantial efforts have been made to classify recent and pending chapters according to their evaluative purpose. Under this framework, the key differentiation made is between functional and physical performance tests and physicochemical tests.

In a general sense, physicochemical testing assesses the chemical quality and implications of the package component or system. In most cases, physicochemical tests evaluate the materials of the container component or system to ensure purity and the absence of harmful contaminants or residuals from the manufacturing process. This has large implications for product safety, but also compatability with the drug product. Physicochemical testing also includes chemical characterization and evaluations of interactions between the package and drug product through extractables and leachables testing or glass delamination testing. Specific physicochemical tests include:

- USP <661.1> Plastic Materials

- USP <661.2> Plastic Containers

- USP <660> Glass

- USP <381> Elastomers

- USP <670> Auxiliary Packaging Components

- USP <1660> Glass Delamination

- USP <1663 / 1664> Extractables and Leachables

- EP EP 3.1.5 Polyethylene with Additives for Containers Parenteral/Ophthalmic

- EP 3.1.6 Polypropylene for Containers and Closures for Parenteral/Ophthalmic

- EP 3.1.3 Polyolefins

- EP 3.1.11 PVC

- EP 3.2.1 Glass Containers for Pharmaceutical Use

- EP 3.2.9 Rubber Closures (Elastomeric)

- EP 3.1.9 Silicone Elastomer

- EP 3.1.1.4 Materials Based on Plasticised Poly (vinyl chloride) for Containers for Aqueous Solutions for Intravenous Infusion

- EP 3.1.15 Polyethylene Terephthalate for Containers for Preparations not for Parenteral Use

- EP 3.2.2.1 Plastic Containers for Aqueous Solutions for Infusion

- JP Section 7 Testing

With access to state-of-the-art laboratory equipment operating within a cGMP, fully electronic, Part-11 compliant quality and data management system, the team at CS Analytical is able to fulfill physicochemical test requests for package components and systems to meet regulatory requirements.