Package (shipment) Distribution Testing is designed to simulate the distribution environment in a controlled laboratory setting where processes (methods) can mimic the hazards that the shipment may endure in the real-world setting. The common test methods used for this type of testing fall under two organizational categories: ASTM (American Society for Testing and Materials) and ISTA (International Safe Transit Association). Both organizations produce peer-reviewed test standards that are readily accepted and recognized. While ASTM covers a broad-spectrum of product and material types that fall far beyond just distribution testing, ISTA, as an association, is solely focused on the package distribution environment. For ASTM, in comparison to ISTA methods, we are specifically referencing ASTM 4169 “Standard Practice for Performance Testing of Shipping Containers and Systems”.

Package (shipment) Distribution Testing is designed to simulate the distribution environment in a controlled laboratory setting where processes (methods) can mimic the hazards that the shipment may endure in the real-world setting. The common test methods used for this type of testing fall under two organizational categories: ASTM (American Society for Testing and Materials) and ISTA (International Safe Transit Association). Both organizations produce peer-reviewed test standards that are readily accepted and recognized. While ASTM covers a broad-spectrum of product and material types that fall far beyond just distribution testing, ISTA, as an association, is solely focused on the package distribution environment. For ASTM, in comparison to ISTA methods, we are specifically referencing ASTM 4169 “Standard Practice for Performance Testing of Shipping Containers and Systems”.

The most common question when working to develop a package simulated distribution test plan is which method should be followed: ASTM 4169 or a specific ISTA standard?

The ASTM method tends to be most commonly used by regulated industries (pharma & medical device) due to ASTM being an FDA recognized standard. This test method is performed by subjecting shipping units to a test plan consisting of a sequence of hazard elements which could / would be encountered in various distribution environments. This approach, which requires the operator to define the formal test plan, provides a uniform basis of evaluating, in a controlled and repeatable laboratory environment, the ability of the shipping unit and its contents to withstand the distribution environment.

On the other hand, ISTA standards have been developed based upon very specific package types and the distribution environment they are expected to encounter based upon the shipment modality. As such, the ISTA methods provide very detailed step by step instructions for that specific package type whereas the ASTM methods require more insightful operator input.

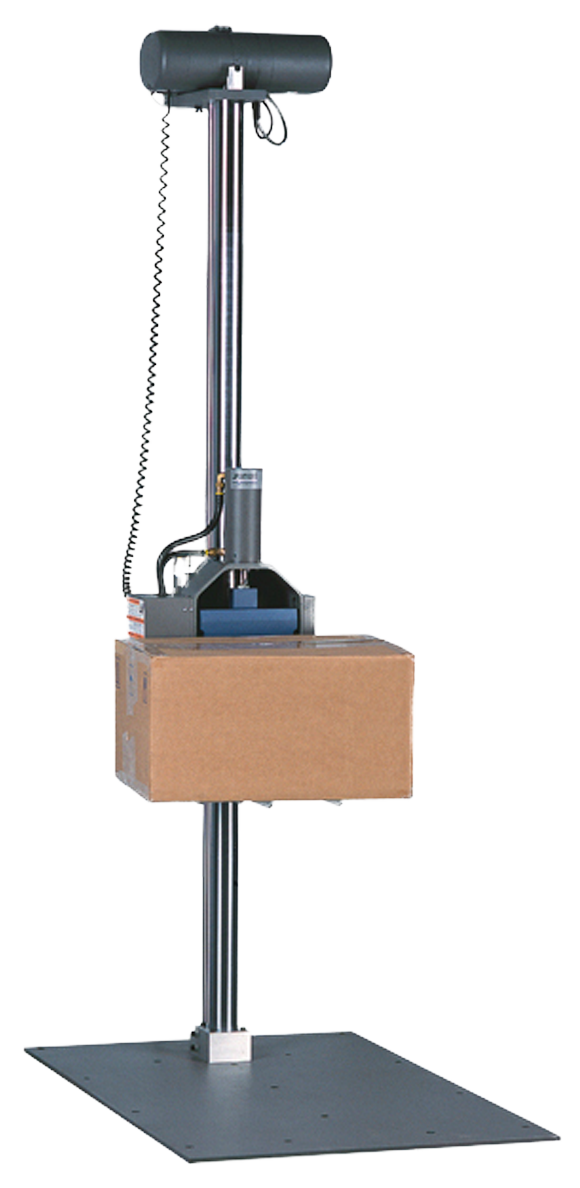

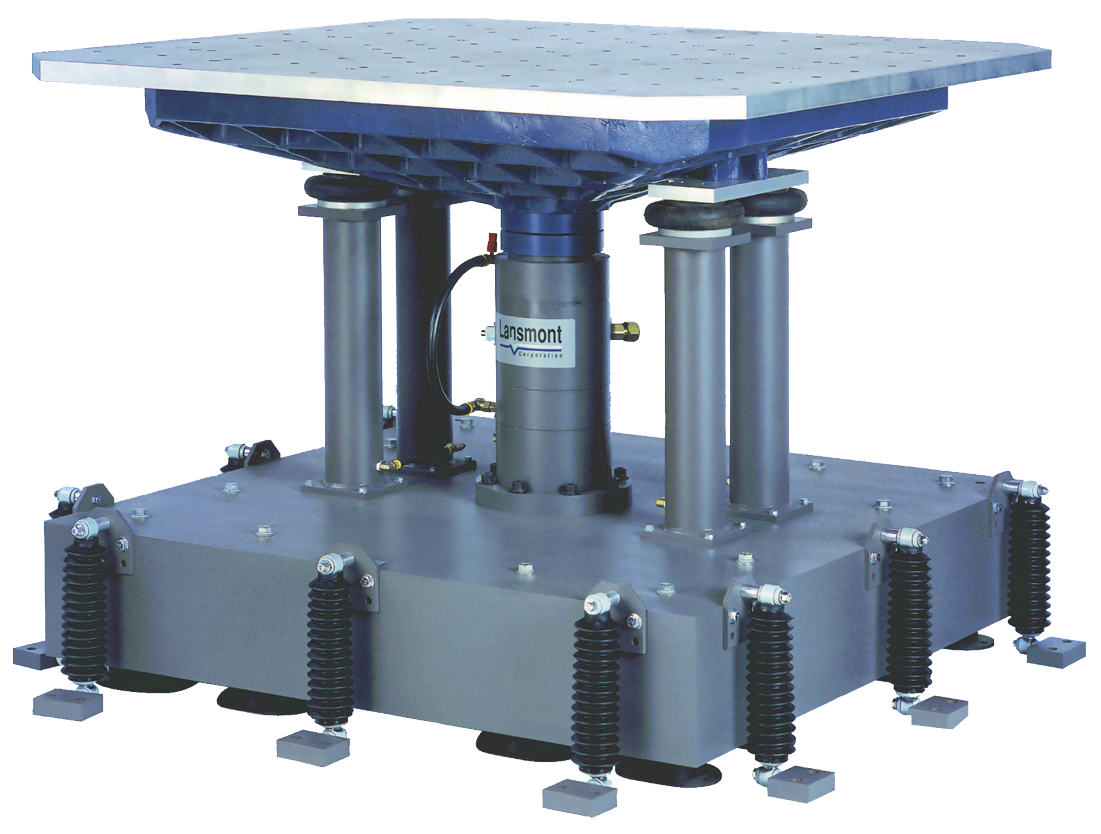

In a more direct comparison, both ASTM 4169 and ISTA Standards address the critical segments of package distribution testing: vibration, shock (drop), compression and atmospheric impact. While the actual test performance in each of these areas may vary between the two options (drop height for a package may be lower with ASTM method vs a comparable ISTA standard), both approaches meet the end objective – evaluation of the package system to withstand the hazards it may face.

In a more direct comparison, both ASTM 4169 and ISTA Standards address the critical segments of package distribution testing: vibration, shock (drop), compression and atmospheric impact. While the actual test performance in each of these areas may vary between the two options (drop height for a package may be lower with ASTM method vs a comparable ISTA standard), both approaches meet the end objective – evaluation of the package system to withstand the hazards it may face.

As noted, ASTM 4169 does offer the advantage of enabling the operator to “customize” the specific test plan to align with the specific package system being tested. One key component of note is the Assurance Level. ASTM 4169 outlines the option to test to a specific Assurance Level (I, II, II) – with Level I being less stringent than Level III.

On the other hand, ISTA standard offers better “ease of use” as the specific test plan and sequence of events is distinctly defined. ASTM requires more upfront planning and test plan development.

The post test inspection and assessment process also tends to be more complicated, and thus user defined, under the ASTM 4169 method. ISTA standards grant more leeway in determining a direct parallel between internal and external damage via the visual inspection process.

In defining the most optimal approach, the same information is required: package size (length, width, height) and weight, a detailed description, quantity and configuration of the product that it will hold, any additional details in package buffer materials (foam liners, cardstock divider plates, foam peanuts, etc.) and what is the expected shipment process (airplane, parcel truck, ocean freighter, long haul trucking, railroad). With this information, using ASTM 4169 an operator can work though the 18 defined distribution cycles and determine a very specific and optimal test protocol. Alternatively, this information can be “plugged into” one of the clearly defined and detailed ISTA standard methods to determine the specific test program to be used. Hence, there is no right answer as the results of either ASTM 4169 or a comparable ISTA standard will ultimately yield similar results and most importantly, be readily accepted by the regulatory agencies.

CS Analytical offers complete ISTA and ASTM 4169 testing programs for a wide variety of product and package types covering a broad spectrum of distribution modalities. Our team has experience designing and developing test programs that meet the specific need of the client, the package and the expected distribution environment. In addition, we offer a host of custom approaches that can be applied to any type of product. The team can also coordinate unique USP 1207 Container Closure Integrity Test programs that add a package distribution component to a standard CCI leak testing program which is now a key European Regulatory Requirement published in Annex 1.