Infrared Spectrophotometry, often referred to us as IR testing or Multiple Internal Reflectance testing, is an established USP test procedure that serves as an ideal identification and confirmation test specific to the type of plastic. This test is refenced in the current USP <661> Packaging Systems and their Materials of Construction as well as the “to be effective December 1, 2025”, USP <661.1> Plastic Materials of Construction general chapter. Like we have done with the article specific to Thermal Analysis testing, this paper will provide and overview of the IR / MIR testing, a description of the instrument, and the procedural steps in the formal testing process.

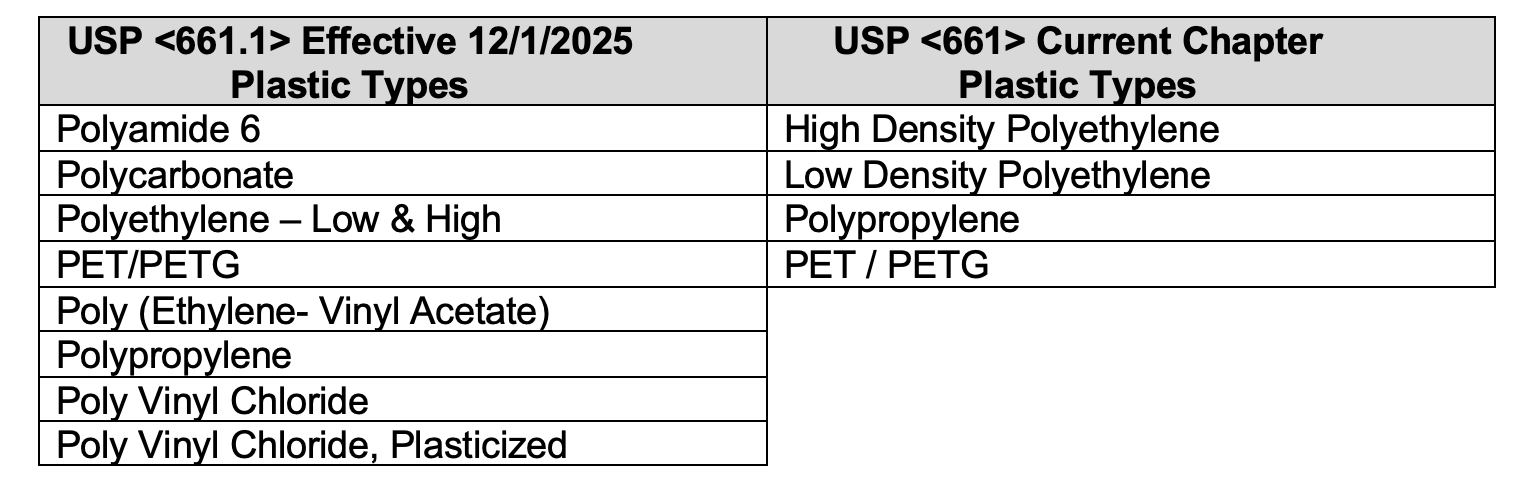

Similar to the Thermal Analysis test, the IR testing differences between the current USP <661> chapter and the USP <661.1> chapter is simply the types of plastics covered. As noted in the table below, the USP <661.1> chapter covers a larger sampling of plastic types. The key to this testing, regardless of plastic type, is that all sample test results are compared to a USP reference standard for the plastic type.

Apparatus (instrument for testing): Using an Infrared Spectrophotometer instrument, IR Spectroscopy measures the radiation by way of reflectance of the material. In layperson’s terminology, a graphical scan of the sample is created and compared to the scan of the USP reference standard. As defined in the USP, the instrument must be fitted with a Multiple Internal Reflectance Sample holder designed and used specifically for testing plastic sample types.

Key Procedural Steps: From your plastic sample, cut two flat sections representative of the average wall thickness of the container, and trim them as necessary to obtain segments that are convenient for mounting in the multiple internal reflectance accessory.

Care must be taken to avoid scratching the surfaces. Each section should be wiped with dry paper or, if necessary, clean them with a soft cloth dampened with methanol, and permit them to dry. Once prepared securely mount the sample to the instrument ensuring adequate surface contact. IR spectrum scanning is based upon cm−1 and the range of the scan is based upon the specific plastic type. For example, Polyethylene is scanned from 3500 to 600 cm−1 and PET and PETG are scanned from 4000 to 400 cm−1. With today’s advanced instruments, the test program for each plastic type may be programmed into the instrument so long as all 21 CFR Part 11 System Validations are in place. Upon completion of the sample scan at the assigned wavelengths, the USP Reference Standard for that plastic type is to be scanned in a similar manner.

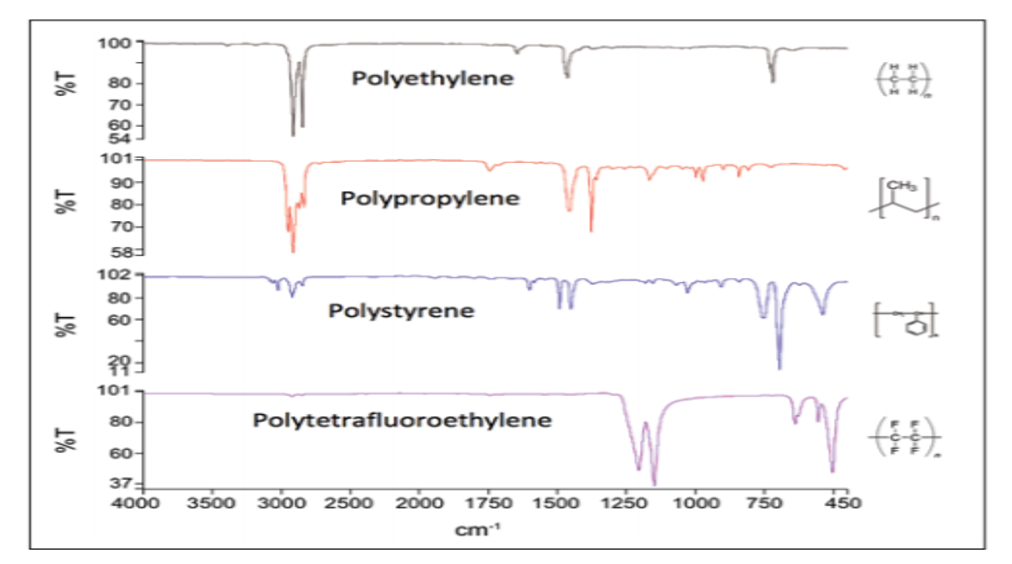

Acceptance Criteria: The acceptance criteria, regardless of plastic type, is basically the same: The corrected spectrum of the sample exhibits major absorption bands only at the same wavelengths as the spectrum of the respective USP reference standard for that specific type that is similarly determined. Once again, in layperson’s terms, the scan must look similar. If need be, the major absorption bands can be numerically displayed at key peak points as an added step to ensuring similarity. But note, this is not a specific requirement outlined in the assigned USP.

An example of what IR scan look like for various plastics

IR Testing for plastic materials is a simple identification required by the USP as a means to ensure the plastic being used meets the USP standards. It is also an ideal test to use for simple, incoming component quality control testing as results can be generated in a short time period and it is relatively inexpensive. When using a third party vendor, it is advisable to ensure that the issued test reports includes the raw data scans for both the sample and the USP reference standard.