Understanding the qualification testing required for your package system enables you to make better and more informed decision on how best to plan and source testing. Two simple, but critical USP <661> an UPS <661.1> qualification tests are Multiple Internal Reflectance (MIR) and Thermal Analysis. Both tests serve to confirm, against a USP Reference Standard, the type of plastic material being used for the container system. In this article will provide and overview of the Thermal Analysis testing, a description of the instrument, and the procedural steps in the formal testing process.

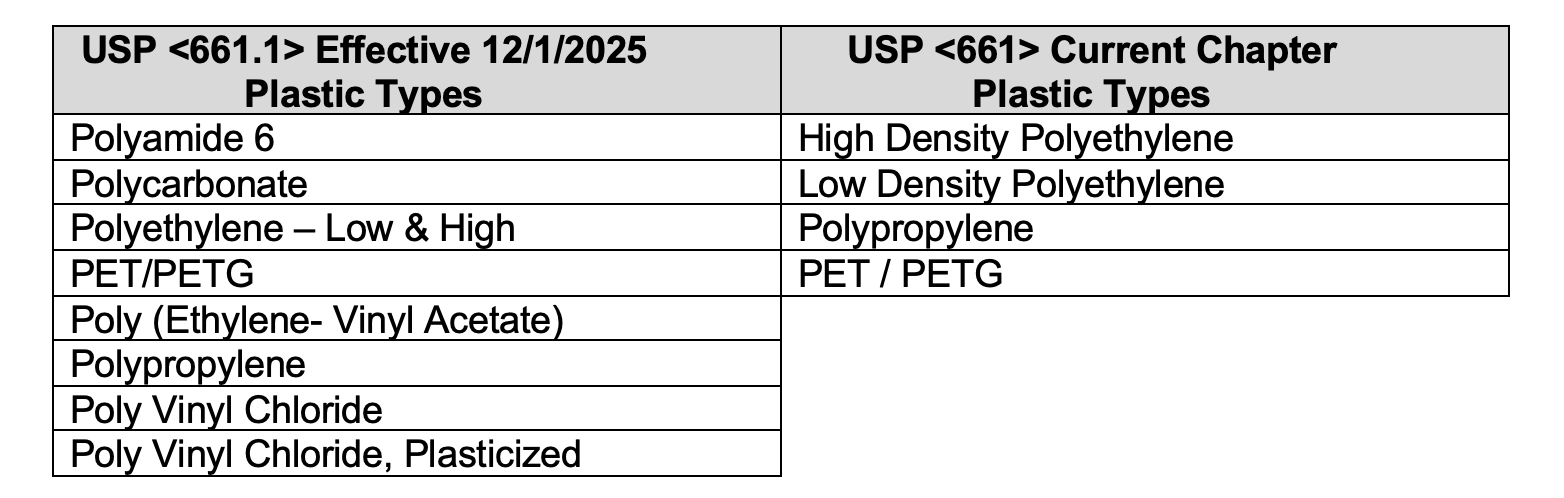

Thermal Analysis testing is referenced in two USP General Chapters: USP <661> Packaging Systems and their Materials of Construction (currently in effect) and USP <661.1> Plastic Materials of Construction which will become effective December 1, 2025. The procedural steps are the same for both USP general chapter referenced so it is advisable that both USP references be documented on the test report. The key difference between the USP <661> current chapter and the to be effective in 2025 USP <661.1> chapter are the list of plastic types covered. As you will not from the following table, the USP <661.1> chapter is much more expansive when it comes to types of materials covered.

Apparatus (instrument for testing): Thermal Analysis Testing is done using a Differential Scanning Calorimeter (DSC). A DSC is a thermo-analytical technique in which the difference in the amount of heat required to increase the temperature of a sample and reference is measured as a function of temperature. In layperson’s terms, the instrument is used to heat and cool the plastic sample thus creating a heating and cooling curve that can be compared to the heating and cooling curve of the USP reference material.

Key Procedural Steps: Cut a plastic section weighing about 12 mg and place it in the test specimen DSC pan ad determine thermal analysis curve using the heating and cooling conditions as specified for the resin type:

Polyethylene (High & Low Density): Heat between 40° and 200° at a heating rate between 2° and 10°/min followed by cooling at a rate between 2° and 10°/min to 40°.

Polypropylene: Heat from ambient to 30° above the melting point. Maintain the temperature for 10 min, then cool to 50° below the peak crystallization temperature at a rate of 10° to 20°/min.

PET: Heat from room temperature to 280° at a heating rate of about 20°/ min. Hold the specimen at 280° for 1 min. Quickly cool the specimen to room temperature, and reheat it to 280° at a heating rate of about 5°/min.

PETG: Heat from room temperature to 120° at a heating rate of about 20°/min. Hold the specimen at 120° for 1 min. Quickly cool the specimen to room temperature, and reheat it to 120° at a heating rate of about 10°/min.

NOTE: For plastic types as listed under USP <661.1> there is wide variability in the assigned sample analysis profile that the DSC must follow.

Acceptance Criteria: Acceptance criteria are assigned based upon the sample type:

Polyethylene (High Density): the melting peak temperature obtained from the thermal analysis curve of the specimen does not differ from that of the Reference Standard by more than 6.0°.

Polyethylene (Low Density): the melting peak temperature obtained from the thermal analysis curve of the specimen does not differ from that of the Reference Standard by more than 8.0°.

Polypropylene: The melting peak temperature in the thermal analysis curve does not differ from that of the Reference Standard by more than 12.0°.

PET: the thermal analysis curve of the specimen is similar to the thermal analysis curve of the Reference Standard and the melting peak temperature obtained from the thermal analysis curve of the specimen does not differ by more than 4.0°

PETG: the thermal analysis curve of the specimen is similar to the thermal analysis curve of the Reference Standard and the melting peak temperature obtained from the thermal analysis curve of the specimen does not differ by more than 6.0°.

Thermal Analysis testing is an ideal approach to not only full materials qualification when completing the entire USP Monograph, but also serves as a quality control test for incoming, plastic components. Having a basic understanding of the test procedures and the assigned acceptance criteria for each plastic type will enable you to better source thermal analysis testing (DSC) and understand the results provided. It is critical to know that testing must always be compared to the assigned USP reference standard for the plastic type and the final report must include quality reviewed copies of the Thermal Scan for both the sample and the USP reference standard.